|

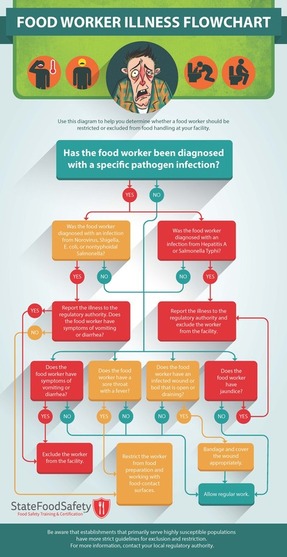

In the midst of cold and flu season, is your employee health policy equipped to handle illness safely and also keep your business running smoothly? Make sure you have a clear protocol on different health conditions and which actions they require. This chart from Statefoodsafety.com may be helpful to post, though your policy might be more stringent if you serve highly susceptible populations. Set procedures for reporting illness, as well as a back-up plan for staffing when you need substitutions, whether you keep your regular pool of employees on standby in case you need them, or if you’re using services like Jitjatjo to hire substitute workers at the last minute.

In the wake of recent reports that the FDA and CDC knew of three E.coli outbreaks connected to romaine lettuce that infected nearly 300 people and killed six, a number of researchers in the food safety industry have gone on the offensive. The editor of Food Safety News, for one, declared that in articles it prints about the agencies in the coming weeks, it would attach warning language saying “both agencies have shown a reckless disregard for the public’s right to know, and their reliability going forward remains suspect.” Restaurant operators can decide for themselves how much trust to place in the agencies when it comes to their supply chains, but in the meantime, some are taking actions ranging from omitting menu items with poor track records on contamination to relying on product recall coverage to protect their business in the case of an outbreak.

If you offer grab-and-go foods, adhering to food safety procedures can be especially difficult. The food auditor Steritech found a number of common food safety issues in 3,000 recent reviews of fresh and prepared foods at grocery stores. Their lessons can also apply to restaurants offering prepared foods to go. Of the problems Steritech discovered, several stood out: One major issue across the board was unclean food contact surfaces, particularly when businesses offer a wide range of prepared foods that require the use of more utensils, equipment and prep areas. Further, contamination via chemical, physical and/or biological hazards was among the top food safety challenges in all departments except produce. Specifically, allergen contamination was a pressing concern for bakery items (demonstrating the need for clear labeling) and improper storage and placement of raw items was an issue in meat, seafood and deli products. Finally, cold holding was among the top problems for produce, seafood, deli and general grocery items – with the principal issue being the temperature of display cases for pre-cut and prepared foods. Make sure these foods are kept at a temperature of 41 degrees or below to prevent the growth of harmful bacteria.

As cold and flu season threatens to impact your staff, make sure you’re minimizing the spread of germs after handwashing. Statefoodsafety.com advises that after washing hands for 20 seconds with soap and water, it’s best to turn off the faucet with a paper towel and then dry hands with either a paper towel or hand dryer. Avoid using a cloth towel, which can contaminate your hands and spread germs.

As winter approaches, your restaurant becomes an even more appealing haven for pests. If pests are a recurring or ongoing problem in your facility, there is (of course) technology that can help. Internet of Things devices and cloud computing have extended to the pest management business, and for operations that need it, the technology can provide 24-hour-a-day monitoring. A restaurant can use sensors within its facility to identify current and emerging risks, collect data that can help minimize the risk of infestations, manage service records across multiple operations and automate reporting required for compliance purposes.

Staying on top of the maintenance of your facility and equipment can help you avoid accidents and costly repairs or replacements. But where should you focus your energy? In a recent NextRestaurants report, Warren Wu of UpKeep, a software firm that helps businesses manage their maintenance needs, identified four top priorities for preventive maintenance in restaurants: First, clean and sanitize your refrigerators each week. Wu advises that during those sessions, staff should check areas that are prone to failure such as door hinges and gaskets. Second, clean burners, grates and flattops daily to minimize grease buildup, which can cause fires and attract pests. Third, on a weekly or monthly basis, scan your facility for a pest problem or conditions that might cause one – like spills that aren’t promptly cleaned or food being stored improperly. Finally, if you serve beer, clean your keg lines no less frequently than every six weeks to prevent mold, bacteria and other residue from building up.

A food thermometer is the only trustworthy way to determine whether or not food is cooked to a safe temperature. Just make sure to take precautions to prevent cross-contamination when using them. Statefoodsafety.com advises operators to clean and sanitize food thermometers between uses, which can be especially easy to neglect when you are using one thermometer to monitor the temperatures of different foods in quick succession.

Chicken causes more foodborne illness than any other food, according to the U.S. Centers for Disease Control and Prevention. To safeguard your operation, make sure your kitchen team washes their hands for 20 seconds with soap and water (and then dries them with a clean towel) before handling chicken – and repeats this as soon as possible after handling raw proteins thereafter. Prepare other raw foods first and remove them from the prep area to avoid cross-contamination. Never wash the chicken as doing so can transfer dangerous bacteria onto your sink and around your kitchen. Cutting boards and utensils used for chicken should be kept apart from those used for other foods. Cook poultry to 165 degrees and use a food thermometer to make sure it has reached the right temperature.

Inadequate cleaning of food-contact surfaces remains the top food safety problem at restaurants. That’s according to a recent review of 250,000 food safety inspection assessments from the past year by the Steritech Institute, which administers food safety training certification. Chris Boyles, vice president of the Steritech Institute, told Fast Casual that the most problematic areas of restaurants tend to be the inside of ice machines, as well as soda fountain nozzles and cutting boards. To prevent the growth of bacteria on these surfaces, have clear training and monitoring procedures for cleaning and sanitizing. For example, any equipment that must be disassembled to be cleaned and sanitized each day should be left to air dry and then checked by the opening and closing managers to verify that the item has gone through the proper procedures.

|

subscribe to our newsletterArchives

April 2024

Categories

All

|

RSS Feed

RSS Feed